Sheet metal usually refers back to the use of fabric below 3mm thick, but laser cutting and bending can be utilized on supplies in excessive of this with ease. The pliability of the method relating to selection of products, thicknesses and complexity of the sections it may create can make it perfect for creating a big range of elements, Employed in each individual marketplace from automotive, transport, domestic appliances, household furniture, industrial tools plus more.

On the other hand, for people who value top quality and lead time, RapidDirect is often your golden fleece. With our engineering help, you may switch your models into truth and shoot you above your rivals in no time.

One of the most essential aspects which can Participate in a role in several of the sheet metal bending approaches is springing back again. When not effectively managed, sheet metal can “spring again” to its initial variety following bending.

Hems are simply folds at the edges of components to supply edges which might be rounded. In fact, you'll find 3 hem types, Each and every owning its own list of structure procedures. For open hems, the inside diameter should be equal on the sheet metal thickness in a minimal simply because diameters which can be also significant will compromise circularity.

We suggest Expert set up by a qualified photo voltaic installation business to ensure appropriate attachment and maintain get more the roof’s waterproofing.

On the other hand, due to the fact a shingle roof doesn’t last as prolonged, you may fork out much more down the road to restore or switch it.

In the united states, copper and lead roofs appeared on essential community properties beginning in the 18th century, including Big apple’s Town Hall in 1764. Via the mid-1800s, metal roofing grew to become additional common as mass-made steel started covering everyday houses and barns.

The brake press can be employed for an exceedingly wide range of sheet and plate supplies. From 0.5mm sheet up to 20mm plate and over and above. This is due to the flexibility of the tooling, and the high electrical power of hydraulic machinery. Brake presses are specified by two general parameters: Tonnes and Width.

(A push brake is a simple machine employed in sheet metal bending procedures, it types preferred bends around the sheet by Operating to clamp the sheet metal in place for push amongst the punch as well as the die)

If your bends need to be close with each other workarounds may be used to empower this, and also employing supplementary procedures which include welding or bolting for getting to the correct geometry. Get in touch To learn more if this is necessary.

As with all bending processes, some spring again is witnessed, as well as the section is normally rolled to a slightly tighter radius than required.

Bending may perhaps go away die marks in your parts, but these marks are purely cosmetic and will likely not have an impact on your part in any way. When we don’t offer any security to stop die marks, they’re uncomplicated to eliminate having a DA orbital sander soon after you get your pieces.

Coining can be a bending method broadly used for its precision and its distinctive capacity to create distinguishing sheets.

Parts which might be being processed working with bending devices should be created through the outset with the restrictions and traits of the process in your mind.

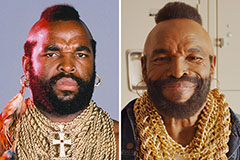

Mr. T Then & Now!

Mr. T Then & Now! Brian Bonsall Then & Now!

Brian Bonsall Then & Now! Andrea Barber Then & Now!

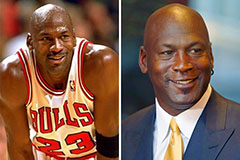

Andrea Barber Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!